Navigating the Modern Electronics Components Supply Chain

Heros Rising

Understanding Electronics Components Supply in Today’s Market

The global electronics industry thrives on innovation, miniaturization, and rapid product development cycles. At the heart of every electronic device—be it a smartphone, medical equipment, or an industrial control system—are individual electronic components. These range from simple resistors and capacitors to complex integrated circuits (ICs) and microcontrollers. The consistent and timely availability of these parts is governed by what we call electronics components supply, a critical segment of the broader electronics manufacturing ecosystem.

In recent years, disruptions such as geopolitical tensions, pandemics, natural disasters, and surges in demand have exposed vulnerabilities in the traditional supply chains. As a result, managing electronics components supply has become more challenging—and more important—than ever before. Manufacturers can no longer rely solely on just-in-time inventory models; they now need resilient, diversified, and transparent sourcing strategies.

This article explores the current landscape of electronics components supply, identifies common challenges, and outlines best practices for securing high-quality components efficiently and sustainably.

Key Components in the Electronics Supply Chain

Before diving into supply dynamics, it's essential to understand what constitutes electronics components supply. This term refers not only to the physical parts but also to the network of suppliers, distributors, brokers, and logistics providers involved in delivering those components to manufacturers.

Common Electronic Components

Typical components sourced include:

- Passive Components: Resistors, capacitors, inductors.

- Semiconductors: Diodes, transistors, MOSFETs.

- Integrated Circuits (ICs): Microcontrollers, memory chips, logic gates.

- Connectors & Switches: Board-to-board connectors, USB ports, tactile switches.

- Power Management Devices: Voltage regulators, DC-DC converters.

- Sensors: Temperature, motion, light sensors.

- Discrete Components: LEDs, crystal oscillators, fuses.

Each of these plays a vital role in circuit functionality, and delays or shortages in any single category can halt production lines.

The Role of Distributors vs. Original Component Manufacturers

Component sourcing typically occurs through two primary channels:

-

Direct from OEMs (Original Equipment Manufacturers): Companies like Texas Instruments, STMicroelectronics, or Analog Devices manufacture and sell their own components. Buying directly ensures authenticity and often better pricing for large volumes.

-

Through Authorized Distributors: Firms like Digi-Key, Mouser, Arrow, and Avnet act as intermediaries. They maintain vast inventories, offer fast shipping, and provide technical support, making them ideal for prototyping and low-to-medium volume production.

However, during periods of shortage, many companies turn to independent distributors or brokers. While these entities can help source obsolete or out-of-stock parts, they carry higher risks related to counterfeit components and inflated pricing.

Challenges Facing Electronics Components Supply

Despite advancements in logistics and digital procurement platforms, several persistent challenges impact the reliability and efficiency of electronics components supply.

1. Global Shortages and Lead Time Delays

One of the most pressing issues in recent years has been prolonged lead times. For example, during the 2020–2023 semiconductor shortage, average lead times for certain ICs stretched from weeks to over a year. According to Wikipedia’s coverage of the 2020–2023 global chip shortage, automotive and consumer electronics sectors were particularly hard hit due to increased demand and factory shutdowns during the pandemic.

Even today, some specialized components face extended wait times, forcing design engineers to consider alternative parts or redesign entire boards.

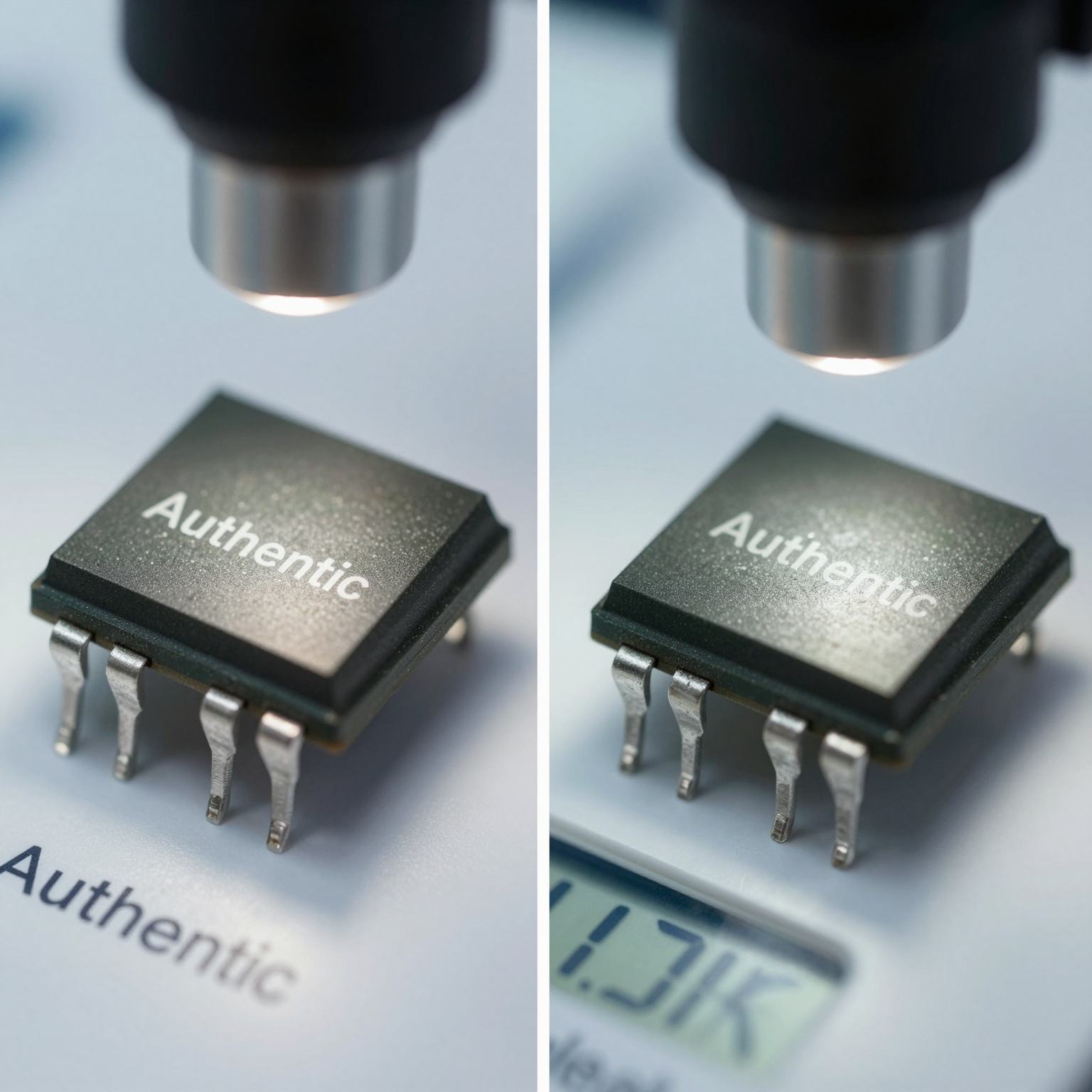

2. Counterfeit Components

Counterfeiting remains a significant risk in the electronics components supply chain. Fake or recycled parts may look identical to genuine ones but fail prematurely under stress, leading to field failures and reputational damage. Independent brokers, especially those operating outside regulated markets, are more likely to distribute counterfeit goods.

To mitigate this risk, reputable manufacturers insist on traceability documentation, including lot numbers, certificates of conformance (CoC), and chain-of-custody records.

3. Obsolescence Management

Electronic components, particularly semiconductors, often have limited lifespans. When a manufacturer discontinues a part (end-of-life or EOL), it creates obsolescence challenges. Designers must either stockpile remaining inventory or redesign the product using newer alternatives—a time-consuming and costly process.

Effective obsolescence management involves proactive monitoring of lifecycle statuses and engaging with suppliers early to plan transitions.

4. Geopolitical and Trade Risks

Trade restrictions, tariffs, and export controls—such as those imposed between the U.S. and China—can disrupt electronics components supply flows. Sanctions on specific manufacturers or technologies (e.g., advanced-node chips) limit access to critical components and force companies to seek alternate sources, often at higher costs.

Additionally, reliance on manufacturing hubs in East Asia introduces logistical vulnerabilities, especially when shipping routes are affected by weather events or political instability.

Strategies for Reliable Electronics Components Supply

Given these challenges, how can electronics manufacturers ensure a stable and secure electronics components supply? The answer lies in adopting strategic, forward-thinking approaches.

1. Dual Sourcing and Supplier Diversification

Relying on a single supplier for critical components is risky. Dual sourcing—qualifying multiple vendors for the same component—increases resilience. If one supplier faces disruption, another can step in.

Similarly, geographic diversification reduces dependency on regions prone to natural disasters or political unrest. For instance, spreading procurement across North America, Europe, and Southeast Asia helps balance risk exposure.

2. Early Engagement with Contract Manufacturers

Partnering early with a contract manufacturer that offers comprehensive electronic component sourcing services can significantly streamline supply chain operations. Such partners often have established relationships with authorized distributors and can leverage bulk purchasing power to secure better pricing and availability.

For example, a full-service PCB assembly manufacturer may integrate component sourcing into its end-to-end production workflow, ensuring seamless coordination between procurement, PCB fabrication, and assembly stages.

This integration minimizes delays and improves traceability, reducing the likelihood of bottlenecks caused by missing parts.

3. Use of Forecasting and Inventory Planning Tools

Advanced forecasting tools powered by AI and machine learning enable companies to predict demand more accurately. By analyzing historical data, market trends, and project timelines, businesses can create realistic component forecasts and place orders well in advance.

Just-in-case (JIC) inventory models, once considered inefficient, are regaining favor in mission-critical industries like aerospace and healthcare, where downtime is unacceptable.

4. Embrace Digital Procurement Platforms

Online marketplaces like Octopart, Chip1Stop, and Sourcengine aggregate real-time pricing and availability data from hundreds of suppliers. These platforms allow engineers and procurement teams to compare options quickly, identify substitutes, and monitor lead times—all from a single dashboard.

They also facilitate transparency and speed up decision-making, which is crucial in fast-moving development environments.

The Role of Quality Assurance in Component Supply

Ensuring that every component meets required specifications isn’t just about functionality—it’s about safety, compliance, and long-term reliability.

Incoming Inspection and Testing

Reputable electronics manufacturers perform rigorous incoming inspection processes. These may include:

- Visual inspection for markings, packaging integrity, and signs of tampering.

- X-ray analysis to detect internal defects in BGA (Ball Grid Array) packages.

- Electrical testing to verify performance parameters.

- Decapsulation for destructive analysis of suspected counterfeits.

These steps form part of a broader PCB quality testing regime designed to catch issues before assembly begins.

Traceability and Documentation

Full traceability—from raw materials to finished products—is increasingly mandated in regulated industries. Each batch of components should come with documentation proving origin, test results, and RoHS/WEEE compliance. This information supports audits, recalls, and warranty claims.

Manufacturers following ISO 9001 or IATF 16949 standards implement strict document control systems to maintain this level of accountability.

Future Trends Shaping Electronics Components Supply

As technology evolves, so too does the electronics components supply landscape. Several emerging trends are set to redefine how components are sourced, managed, and integrated.

1. Increased Adoption of Automation in Procurement

AI-driven procurement assistants can now automatically generate bills of materials (BOMs), suggest alternative components, and even place purchase orders based on predefined rules. This automation reduces human error and accelerates sourcing cycles.

2. Growth of Sustainable and Ethical Sourcing

Environmental, social, and governance (ESG) considerations are influencing electronics components supply decisions. Companies are prioritizing suppliers who adhere to ethical labor practices, use conflict-free minerals, and minimize environmental impact.

Regulations like the EU’s Conflict Minerals Regulation require greater transparency in mineral sourcing, pushing the industry toward more responsible supply chains.

3. Onshoring and Nearshoring Initiatives

In response to global uncertainties, many countries are investing in domestic semiconductor production. The U.S. CHIPS and Science Act, for example, allocates billions to boost local chip manufacturing. Similarly, the European Union aims to double its share of global semiconductor output by 2030.

While full self-sufficiency remains distant, these initiatives will gradually reduce dependence on offshore suppliers and improve regional electronics components supply stability.

4. Integration of Blockchain for Transparency

Blockchain technology holds promise for enhancing traceability and trust in the supply chain. By recording every transaction—from mining raw materials to final assembly—on an immutable ledger, stakeholders can verify authenticity and provenance instantly.

Pilot programs by major tech firms show encouraging results, though widespread adoption is still years away.

Conclusion: Building Resilience in Electronics Components Supply

The electronics components supply chain is no longer a back-office function—it’s a strategic imperative. With increasing complexity and volatility, manufacturers must adopt proactive, agile, and transparent sourcing practices.

Whether through dual sourcing, early collaboration with contract manufacturers, or leveraging digital tools, the goal remains the same: ensuring that the right components are available at the right time, without compromising on quality or cost.

By partnering with experienced providers offering integrated solutions—from PCB fabrication to electronic component sourcing—companies can focus on innovation while leaving the complexities of supply chain management to experts.

As the industry moves toward smarter, greener, and more resilient systems, mastering electronics components supply will remain a cornerstone of competitive advantage.