Reliable PCBA Solutions: Ensuring Quality and Performance in Electronics Manufacturing

Winnie King

Why Reliable PCBA Solutions Are Critical for Modern Electronics

In today’s fast-paced world of electronics, the reliability of printed circuit board assembly (PCBA) has become a cornerstone of product success. From consumer gadgets to industrial automation systems, every electronic device depends on a well-designed and accurately assembled PCB to function as intended. But not all PCBA processes deliver the same level of quality or consistency.

Reliable PCBA solutions go beyond simply placing components on a board — they encompass precision engineering, rigorous testing, supply chain integrity, and adherence to industry standards. When companies invest in dependable PCBA services, they minimize field failures, reduce warranty claims, and enhance customer satisfaction.

As devices grow more complex — with tighter tolerances, higher component density, and increased power demands — the need for consistent and trustworthy assembly practices becomes non-negotiable. A single faulty solder joint or misaligned microchip can lead to catastrophic system failure, especially in mission-critical applications like medical devices or aerospace technology.

This article explores what makes PCBA solutions truly reliable, the key factors that contribute to long-term performance, and how partnering with the right manufacturer ensures your products meet both technical and commercial goals.

What Makes a PCBA Solution “Reliable”?

The term reliable in the context of PCBA solutions refers to consistent performance over time under expected operating conditions. However, achieving reliability requires attention to multiple stages of the manufacturing process.

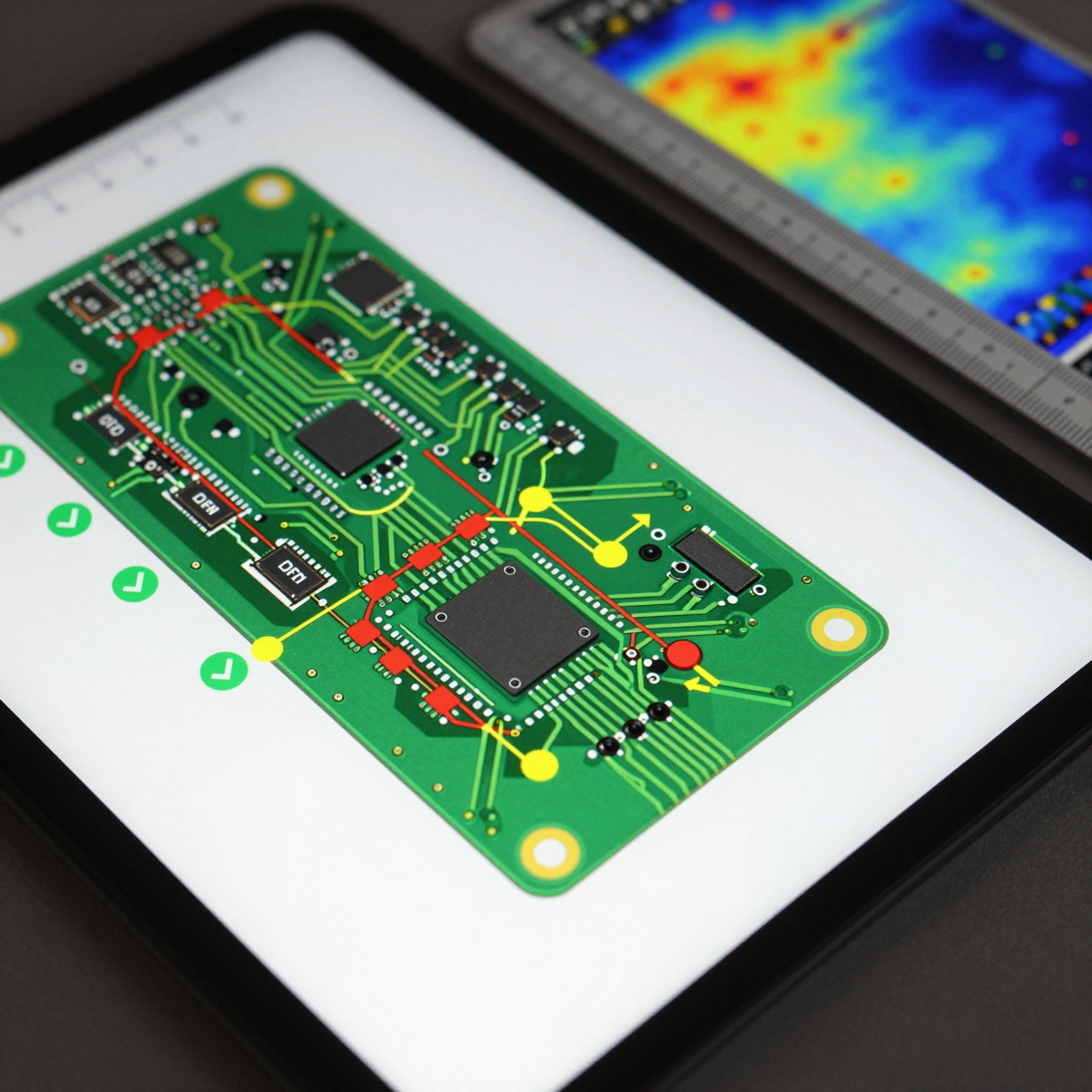

1. Design for Manufacturability (DFM)

Before any physical production begins, a robust design is essential. DFM analysis ensures that the PCB layout is optimized for efficient and error-free assembly. This includes checking component spacing, pad sizes, trace widths, and thermal considerations.

A design that ignores manufacturability often leads to bridging, tombstoning, or poor reflow results — all of which compromise reliability. By catching these issues early, manufacturers can avoid costly redesigns and delays.

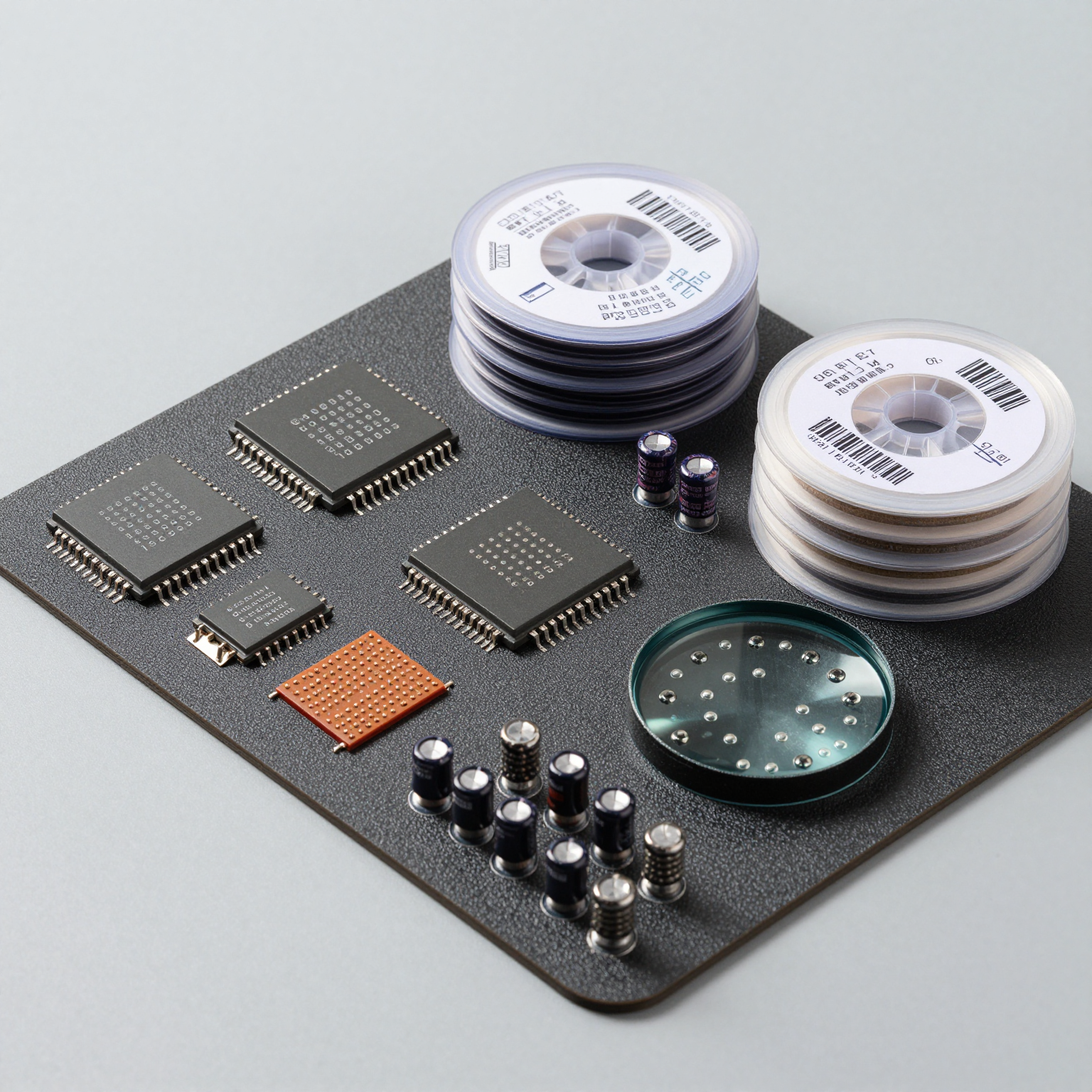

2. High-Quality Component Sourcing

One of the most overlooked aspects of reliability is component sourcing. Using counterfeit, expired, or substandard parts may save money upfront but introduces serious risks down the line.

Top-tier reliable PCBA providers implement strict procurement protocols, including:

- Verification through authorized distributors

- Date code and lot number tracking

- Incoming inspection and X-ray analysis for BGAs and hidden leads

These measures ensure that only genuine, high-performance components are used in final assemblies.

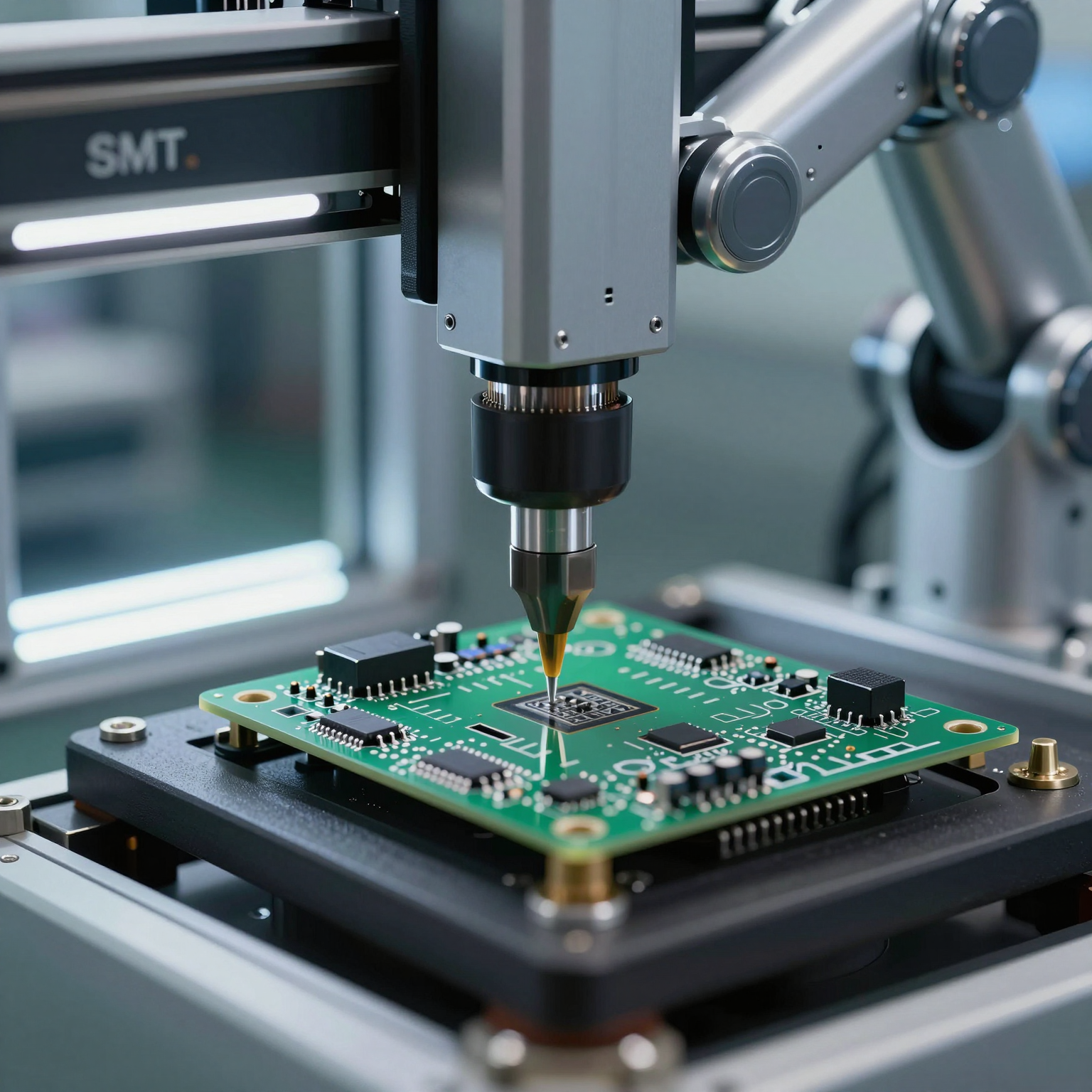

3. Precision Assembly Processes

Modern PCBA relies heavily on automated technologies such as surface mount technology (SMT) and automated optical inspection (AOI). These tools provide repeatability and accuracy far beyond manual methods.

For instance, pick-and-place machines can position components within microns of their target location, while reflow ovens follow precise thermal profiles to create strong, void-free solder joints. Any deviation from optimal parameters increases the risk of latent defects.

Moreover, advanced techniques like BGA assembly require specialized expertise due to the hidden nature of the connections. Without proper X-ray inspection and rework capabilities, undetected faults can persist into end-use environments.

Learn more about overcoming common challenges in BGA assembly challenges.

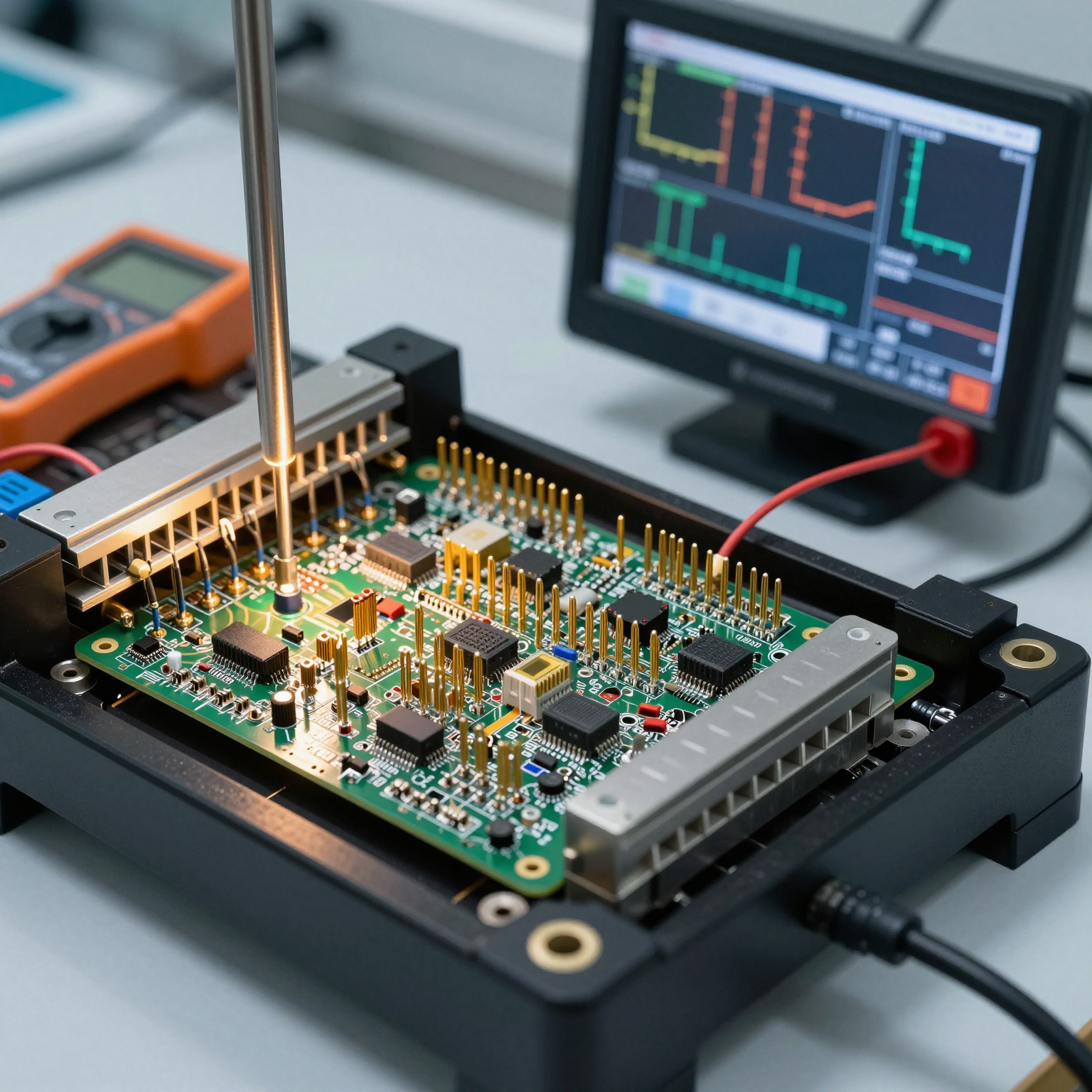

The Role of Testing and Quality Assurance

Testing isn't an afterthought — it's integral to delivering reliable PCBA solutions. A comprehensive QA strategy involves multiple layers of verification throughout the production cycle.

In-Circuit Testing (ICT)

ICT checks individual components for correct value, orientation, and connectivity. It detects opens, shorts, and misplaced parts immediately after assembly, allowing for quick correction before boards move further down the line.

Functional Testing

While ICT verifies electrical correctness, functional testing simulates real-world operation. This step confirms that the assembled PCB performs its intended tasks — whether it's processing signals, communicating over Wi-Fi, or driving motors.

Functional test fixtures are customized to each product, ensuring full coverage of operational modes. For high-reliability sectors like automotive or defense, this testing is often mandated by regulatory standards.

Environmental Stress Screening (ESS)

To predict long-term durability, some manufacturers subject boards to environmental stress tests such as:

- Thermal cycling

- Vibration exposure

- Humidity testing

These simulations accelerate aging and reveal weaknesses that might not appear during standard operation. Products that pass ESS are far more likely to perform reliably in harsh conditions.

For insight into best practices, explore our detailed guide on the 6-step quality control process.

Industry Standards That Define Reliability

Compliance with recognized industry standards is another hallmark of reliable PCBA providers. These frameworks establish benchmarks for materials, processes, and documentation.

Key standards include:

- IPC-A-610: Acceptability of Electronic Assemblies — defines visual criteria for acceptable solder joints and component placement.

- J-STD-001: Requirements for Soldered Electrical and Electronic Assemblies — outlines workmanship requirements for soldering.

- ISO 9001: Quality Management Systems — ensures consistent processes and continuous improvement across the organization.

- RoHS & REACH: Environmental compliance for hazardous substances.

Manufacturers certified under these standards demonstrate a commitment to quality and traceability. They also maintain detailed records for audits, recalls, or failure investigations.

Choosing the Right Partner for Reliable PCBA Services

Selecting a partner capable of delivering reliable PCBA solutions involves evaluating several critical factors:

Technical Expertise and Equipment

Does the manufacturer use state-of-the-art equipment? Can they handle fine-pitch components, HDI layouts, or mixed-technology boards (SMT + through-hole)? Their technical capabilities should align with your project's complexity.

Understanding the differences between SMT vs through-hole assembly can help you assess whether a provider matches your needs.

Scalability and Flexibility

Whether you're prototyping or ramping up to mass production, your PCBA partner must scale efficiently without sacrificing quality. Look for evidence of lean manufacturing principles, inventory management systems, and responsive communication.

Transparency and Communication

Reliability isn’t just about hardware — it’s also about trust. A transparent partner shares progress updates, test reports, and yield data openly. They collaborate closely during new product introduction (NPI) phases and support design improvements.

Supply Chain Resilience

Recent global disruptions have highlighted the importance of resilient component sourcing. A reliable manufacturer maintains relationships with multiple suppliers, uses forecasting tools, and offers alternatives when necessary.

They may also provide full electronic component sourcing services, reducing your burden and mitigating obsolescence risks.

Applications Where Reliable PCBA Is Non-Negotiable

Certain industries demand exceptionally high levels of reliability due to safety, legal, or financial implications.

Medical Devices

From patient monitors to implantable devices, failure is not an option. Regulatory bodies like the FDA require stringent documentation and validation. Any defect could result in harm, liability, or recall.

Aerospace and Defense

Extreme environments — including high altitude, radiation, and mechanical shock — demand ruggedized designs and flawless assembly. Redundancy and fault tolerance are built into both hardware and software.

Automotive Electronics

With the rise of electric vehicles and advanced driver assistance systems (ADAS), automotive PCBAs must operate flawlessly for years. Failures in braking systems, sensors, or battery management can have life-threatening consequences.

Industrial Control Systems

Factories rely on programmable logic controllers (PLCs), motor drives, and human-machine interfaces (HMIs) to run 24/7. Downtime equals lost revenue, so reliability directly impacts profitability.

How to Evaluate a Manufacturer’s Reliability Claims

Not all claims of "high reliability" are backed by action. Here are practical ways to verify a manufacturer's credibility:

Request Case Studies or References

Ask for examples of similar projects they’ve completed, particularly in your industry. Customer testimonials and third-party reviews offer valuable insights.

Audit Their Facility (Onsite or Virtual)

If possible, tour the facility to observe workflows, cleanliness, and employee training. Many manufacturers now offer virtual audits with live video feeds.

Review Certifications and Compliance Documents

Check for active ISO, IPC, and other relevant certifications. Ask for copies of recent audit reports or quality manuals.

Sample Testing and First Article Inspection (FAI)

Before committing to volume production, request sample builds. Conduct independent testing to validate performance and durability.

Building Long-Term Success with Trusted PCBA Partners

Ultimately, reliable PCBA solutions are not just about avoiding defects — they’re about enabling innovation with confidence. When engineers know their boards will perform consistently, they can focus on pushing boundaries rather than troubleshooting failures.

Partnering with a trusted PCB assembly manufacturer means gaining access to expertise, infrastructure, and peace of mind. You benefit from reduced development cycles, improved time-to-market, and stronger brand reputation.

At every stage — from initial concept to post-production support — reliability should be the guiding principle.

Ready to bring your next project to life with confidence? Contact a PCB manufacturer today to discuss your requirements and get a quote tailored to your needs.